COLD CHAIN PACKAGING

Parcel Cold Chain Shippers

Comprehensive Temperature Controlled Parcel Shippers for Life Sciences

Inmark Life Science sets the industry standard for parcel cold chain packaging, providing global protection for pharmaceuticals, clinical trial materials, biological samples, and regulated healthcare products. Rely on our pre-validated, globally harmonized parcel shipping systems to maintain strict temperature control from departure through arrival, regardless of transit conditions.

Choose from an extensive portfolio of insulated parcel shippers, specifically designed for room temperature, refrigerated, and frozen shipments. Our advanced use of EPS, cellulose, and sustainable insulation materials ensures exceptional and reliable thermal performance. Eco-sensitive shippers like Gentoo™ and Viridis™ feature renewable, recyclable, and biodegradable construction, supporting your sustainability targets without sacrificing shipment integrity

Delivering trusted cold chain integrity for every parcel shipment.

Unmatched Performance and Efficiency

- ISTA 7D validated packaging guarantees thermal reliability & regulatory compliance for clinical and pharmaceutical shipments

- Universal, modular, and seasonal solutions provide true flexibility and rapid pack outs, with no post-conditioning required—ideal for operational efficiency with validated payload sizes from 2L upwards.

- Refrigerants such as dry ice, water-based gels, and advanced phase change materials offer consistent temperature performance for routes up to 192 hours.

- All products are designed for ease-of-use, regulatory compliance, and cost reduction, protecting high-value shipments at every phase

Explore our Parcel Cold Chain Solutions

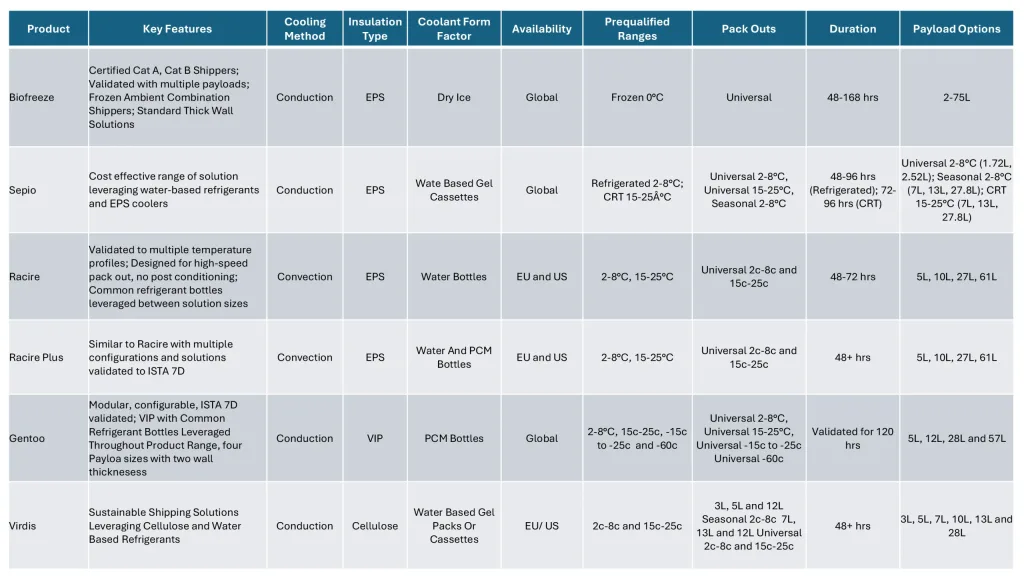

Easily find the right temperature-controlled parcel shipper for your pharmaceutical, clinical, or diagnostic payloads. The grid below showcases Inmark’s industry-leading range of parcel cold chain solutions, with key features, payload capacities, temperature ranges, insulation types, and sustainability highlights for each named shipper.

Compare options side-by-side to select the solution that best fits your shipping requirements, regulatory needs, and sustainability goals. Begin your cold chain journey with confidence—everything you need is at your fingertips.

WHY INMARK LIFE SCIENCE

Leading-Edge Packaging for Every Need

Tailored Protection

Broad Temperature Range

Easy Integration

Extended Performance

Simple, Fast Assembly

Always Available, Worldwide

Top Laboratories and Pharmaceutical Manufacturers Trust Inmark Life Science

With over 45 years of expertise, Inmark Life Sciences brings uncompromising reliability, supported by a dedicated service team that streamlines your product selection and shipping, so you can focus on critical research and patient outcomes.

Optimize Your Cold Chain Today

Inmark Life Science’s temperature-controlled parcel shippers ensure compliant, secure transit for every critical shipment worldwide. Contact us today to learn more.

FAQS

Popular Questions

Temperature-controlled parcel packaging safeguards sensitive products, such as pharmaceuticals, biologics, and food, by maintaining specific temperature ranges throughout shipping, ensuring product integrity and regulatory compliance.

These solutions use insulating materials (like EPS, PUR, or vacuum insulated panels) combined with phase change materials (PCMs) such as dry ice or gel packs, which absorb or release heat to keep payloads within specified temperature ranges for extended periods, even during transit delays.

Products such as vaccines, biologics, blood samples, specialty foods, perishable goods, and high-value biologic pharmaceuticals typically require temperature-controlled parcel packaging to prevent spoilage, contamination, or reduced efficacy.

Our solutions cover a wide range of temperature requirements, with packaging validated for ranges such as -20°C (frozen), 2-8°C (refrigerated), and 15-25°C (controlled room temperature), making them suitable for diverse industry needs.

Modern temperature-controlled parcel packaging can maintain precise temperatures for up to 192 hours (8 days) depending on the configuration, insulation quality, and environmental conditions during transit.

When selecting packaging, key factors include the product’s required temperature range, shipment duration, route conditions, local regulations, and the need for data logging or tracking for compliance and quality assurance.